FORCLAZ

Ref.

8754268

4647179

INFLATABLE MATTRESS PUMP BAG

€16.50

Tax included

Store Availability

Store Availability

Our trekking designers have designed this pump bag to inflate and transport your inflatable trekking mattress.

BENEFITS

Compatibility

Suitable for all Forclaz trek inflatable mattress.

Easy transport

Weighs 60g. Inflation capacity 19L. Cover 3L. Compression straps.

Efficiency

Inflate your Forclaz mattress in 4 or 5 steps!TECHNICAL INFORMATIONS

Directions for use

Unroll the pump bag completely. Connect the valve of the pump bag to the "in" valve of your Forclaz treks. Blow 10 - 20 cm from the entrance of the upper part of the bag, to inflate the main volume. Roll the bag on itself to the valve to push the air out of the main bag into your mattress. Adjust the quantity of air for your comfort (firmness of your mattress).

Use

You pump bag can also be used as a carry cover to store your mattress. We integrated compression straps to adjust the carrying cover to your mattress.

composition

composition

Main fabric: 100.0% Polyester; Back fabric: 100.0% Thermoplastic Polyurethane Polyester Based

Tips for storage and maintenance

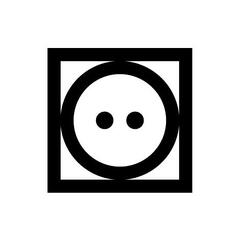

DRYING IN A TUMBLE DRYER POSSIBLE. NORMAL TEMPERATURE, MAXIMUM EXHAUST AIR TEMPERATURE OF THE DRUM 80°C.

DRYING IN A TUMBLE DRYER POSSIBLE. NORMAL TEMPERATURE, MAXIMUM EXHAUST AIR TEMPERATURE OF THE DRUM 80°C.

MAXIMUM WASH TEMPERATURE OF 30°C. VERY MODERATE TREATMENT.

MAXIMUM WASH TEMPERATURE OF 30°C. VERY MODERATE TREATMENT.

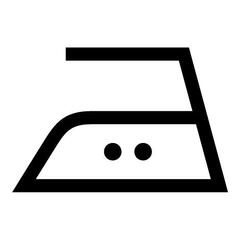

IRON AT A MAXIMUM SOLEPLATE TEMPERATURE OF 150°C.

IRON AT A MAXIMUM SOLEPLATE TEMPERATURE OF 150°C.

MAXIMUM WASH TEMPERATURE 70°C. NORMAL TREATMENT.

MAXIMUM WASH TEMPERATURE 70°C. NORMAL TREATMENT.

IRONING AT A MAXIMUM IRON SOLEPLATE TEMPERATURE OF 200°C.

IRONING AT A MAXIMUM IRON SOLEPLATE TEMPERATURE OF 200°C.

TESTS AND WARRANTY

Warranty

2 Years

Videos

Ecodesign approach

With ecodesign, we reduce the environmental impact of our products.

Analysing the product's environmental footprint enabled us to identify the most impactful stages of its life cycle. Thanks to this approach, our design teams were able to develop this product while significantly reducing its environmental impact.

Ecodesign actions on this product

-

Process

ProcessDope dyed

Product made from 56% dope dyed yarn

Using this mass-dyeing process enables us to reduce CO2 emissions linked to the production of dyed textiles by at least 46% compared to conventional dyeing.

-

Process

ProcessGreige

Product made from 22% undyed yarn

Using this finishing process enables us to reduce CO2 emissions linked to the production of undyed textiles by at least 58% compared to conventional dyeing.